Large format Pneumatic heat press machine wholesale

Purchase Qty / Price:

, China

Member Since: 2010

Company Type:

13660825169

13660825169

Product Description

1.Double silde out working table 2.High pressure 3.Pneumatic auto

Model: HPM-19

Voltage 110V/220V/380V

Power: 9000W/1.2KW/1.4KW

Time range: 0-999s

Temp range: 0-300°C

Printing area: 60cm x 80cm(24"x31")/ 80cm x 100cm(31"x39")/ 100cmx120cm(39"x47")/100cm x 150cm(39"59")/

110cm x170cm(44"x67")/100cm x 200cm(39"x79"

Pneumatic Digital Flat Garment Heat Press Machine

![]()

Specifications

High Grade Silicon Roller Heat Transfer Machine

1.Double silde out working table

2.High pressure

3.Pneumatic auto

Product Description

| Voltage | 110V/220V/380V | ||||

| Power | 9000W/1.2KW/1.4KW | ||||

| Time range | 0-999s | ||||

| Temp range | 0-300°C | ||||

| Printing area | 60cm x 80cm(24"x31")/80cm x 100cm(31"x39")/100cmx120cm(39"x47") | ||||

| /100cm x 150cm(39"59")/110cm x170cm(44"x67")/100cm x 200cm(39"x79") | |||||

| G.W | 500KG/1102LBS---540KG/1190LBS---700KG/1543LBS---930KG/2050LBS--1100KG/2425LBS---1100KG/2425LBS | ||||

| Package size | 137x175x191cm/167x155x170cm/197x165x180cm/218x175*191cm | ||||

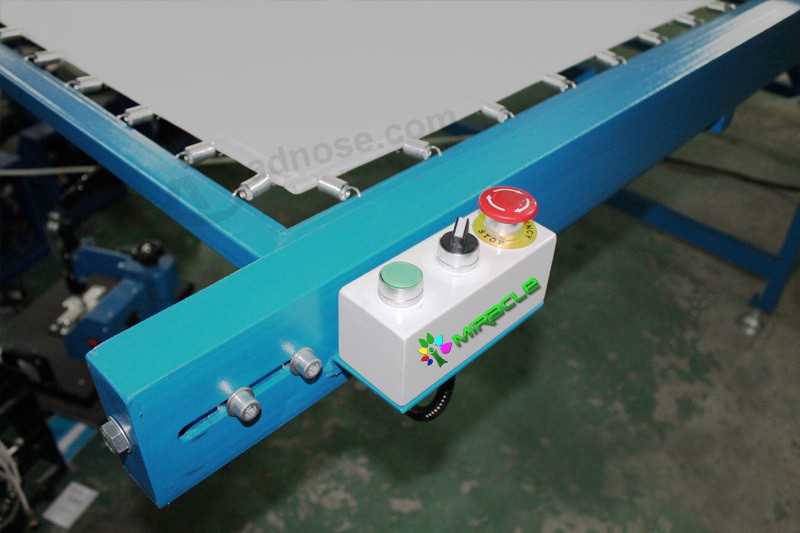

• M2 has double slide out working table but only need one person to operate it.

• More convenient for printing.

• Higher pressure

• Suitable for large size printing meterial.

![]()

Product features

The heating plate surface with Teflon paint, dust, without high temperature cloth.

Intelligent digital display constant temperature controller, temperature control is accurate (+ 10)

Unique front pressure adjustment mode, the pressure adjustment, convenient and flexible

Digital display of electronic time, the process automatically issued a warning tone

Aluminum heating plate, electric tube and plate body pouring into one, uniform heating, durable

The surface of the heating surface is coated with high temperature and anti - adhesive layer, which is convenient for cleaning and anti-oxidation.

The high temperature resilient foaming silicone, 400 for the working table, is unchanged at.

The machine can be any color or monochrome images, text transfer to: ceramic, metal, glass, clothing etc. material, widely used in shop business, transfer personalized products, garment pyrography used.

Use instructions:

Pick up the air source and make the machine open.. The test pressure is appropriate, if not appropriate, adjust the pressure knob. (clockwise to increase the pressure of the knob, counterclockwise rotation to reduce the pressure)

Ready to be hot stamping. (warming up process please do not be hot stamping material placed on the working platform, lest bad)

Open the power switch, the temperature controller began to self, about 10 seconds after the self-test and enter the working state, this time to set the working parameters,

(the first use of a good set of required: temperature, time, details of the attached instrument panel time and temperature operation instructions)

The temperature and time required to set the temperature, the machine starts heating up (the temperature rise to 200 minutes about 15 minutes).

Pending machine to achieve the desired temperature will require transfer of goods tile is placed on the work surface, is pressed down, the machine began to automatic timing, after reaching the set time, the machine automatically open.

Note: if there is an emergency, you need to stop the machine halfway, so that the heating board can rise, you can press the urgent stop button. The next time you use the emergency stop button to spin.

Time temperature setting:

Click the SET button, press 5 or 6 key to set the instrument to display the temperature. (usually 180-220, depending on the material),

Press the SET button again, switch to the setting time, press 5 or 6 key to set the required time (usually 2-3 minutes, depending on the material set).

Press the SET key to return to the standard mode. Set up.

Notes:

Temperature control instrument function is more complex, in addition to setting the temperature value outside do not need to excess regulation, otherwise easy to cause the instrument disorder can not work!!!

If the hot, hot stamping and cold tear, after, please wait 15-20 seconds, it will be hot tear off the paper. If it is hot tear of pyrograph, hot stamping is completed, please immediately hot paper torn off, down clothes lines diagonal tear), successful stamping to the correct time, temperature and pressure together

The final effect is determined to be hot printed material thickness and type of material used and the type of heat transfer paper

Different things should be hot stamping test sample, determine the best stamping time and temperature required for mass production can be good